UHVCVD

UHVCVD SYSTEMS

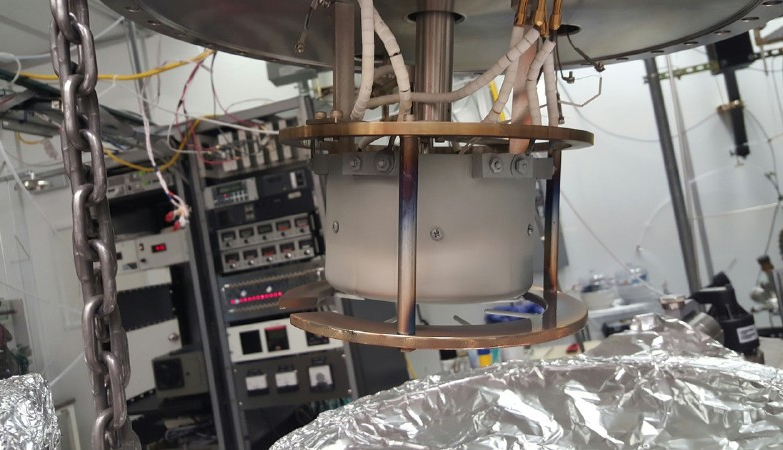

Ultra High Vacuum Chemical Vapor Deposition (UHVCVD) system upgrade.

This system was originally designed with Lamps inside the chamber for the heater. The lamps worked great the first few growths but then they would get coated and the system would have to be vented to replace them. After upgrading the system only has to be vented annually for inspection. The pictures below show the heater after several years of service. We were able to clean the heater and put it back into service, it’s still being used today.

* Water-cooled / heated stage with linear motion and rotation for 6” wafers.

* Boron nitride / paralytic graphite heater mounted to a water cooled SS holder

* Single wafer research system with Load Lock and dry Nitrogen box

* Quartz sample holder

* Type K TC’s

* 800deg C process temp

* Long Life cycles / less downtime and bake-out time

* 2 DC power supplies for dual zone heater and better temperature uniformity

* Tantalum heat shielding and Rods

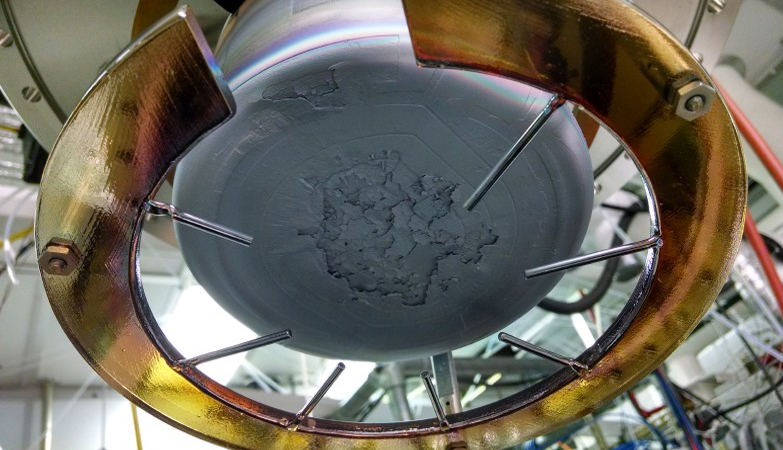

Picture after 3 years of depositions.

The operator forgot to turn on the water cooling after bake-out and coated the electrical contacts so we opened the system and sanded the heater clean.