Orbital Welding

Orbital Welding

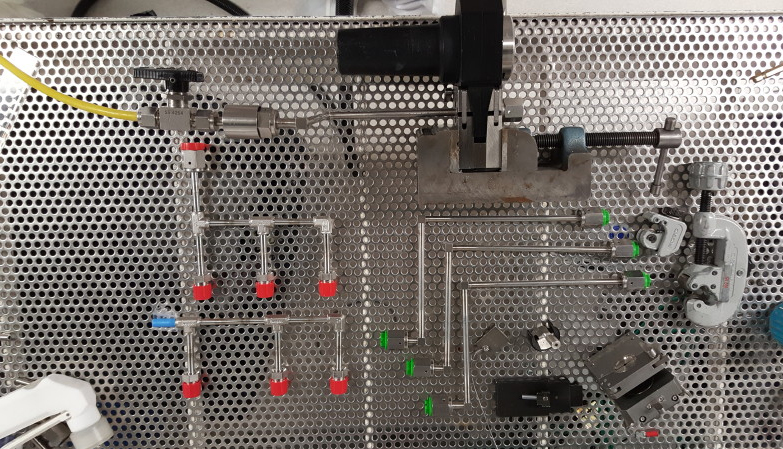

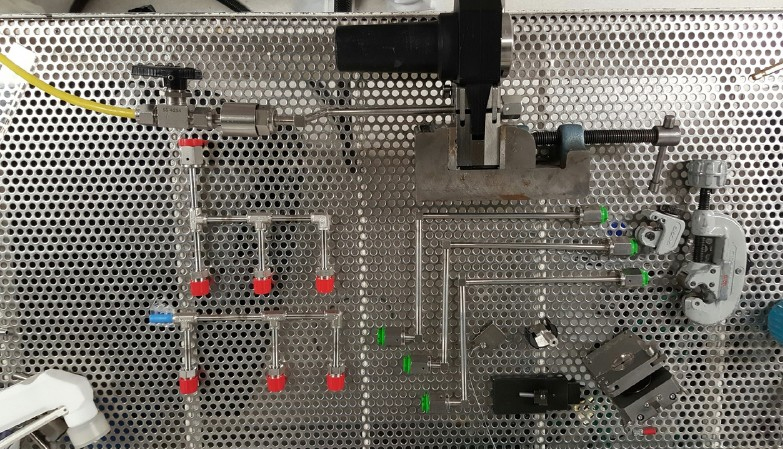

Orbital welding is a specialized area of welding whereby the arc is rotated mechanically 360° around a static workpiece. Ultra-high purity vacuum products has over 16 years’ experience Orbital welding custom gas delivery manifolds for toxic or corrosive gases. We understand your process needs and goals which helps design the best, most cost-effective gas delivery system. From deposition to etch, UHPVP has the expertise to deliver, no matter the application.

High Purity Welding

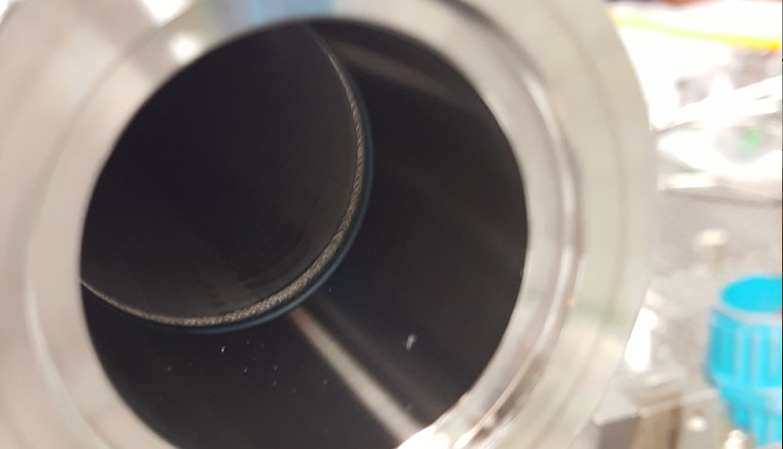

UHPVP understands the importance of keeping particles and moisture out of your process gas lines. Impurities trapped inside the tube could ruin an entire process, and cause a significant loss of time and money. To achieve the cleanest environment possible, all our welding, assembly, leak-checking, cleaning and packaging is done in a class 100 clean room. You can rest assured you will receive a UHP product.

UHPVP orbital welding process

UHPVP specializes in performing cleanroom orbital welding services for high pressure and vacuum manifolds in tubing ranging from 1/8” diameter to 2” diameter. We use argon for both external and internal purges to keep the welds exceptionally clean. Our orbital welds achieve 100% penetration to ensure meeting the customers’ specifications and standards. UHPVP uses computerized orbital welding technology, allowing us to set the welding schedule ahead of time. By being able to specify the specific metal to be welded, our automated machine adjusts the process accordingly and saves a recipe. This automated process saves time and money.